Home ProductGate Valve

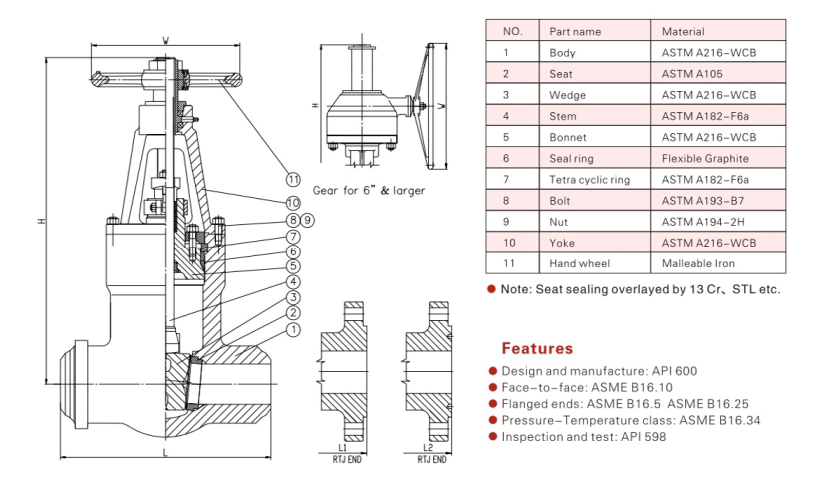

Applicable Standards:

Gate Valve, API600

Steel Valves, ASME B16.34

Face to face ASME B16.10

End Flanges ASME B16.5

Butt Welding ends ASME B16.25

Inspection and test API 598

Material: WC6

Size Range: 2"~16"

Pressure Rating: ASME

CL 900, 1500, 2500

Temperature Range: -29℃~538℃

Solid Wedge Gate Valve is manufactured with solid wedge, which has higher strength. Because the wedge is solid, when working, there will be less de-formation happing to the gate, it will have to depend on the stress from the stem to achieve sealing with seat of valve.

GW produces the following gate valves

Solid Wedge Gate Valve OS&Y,

No Rising Stem Solid Wedge Gate Valve

Rubber Wedge Gate Valve

Soft Wedge Gate Valve

Resilient Seated Solid Wedge Gate Valve

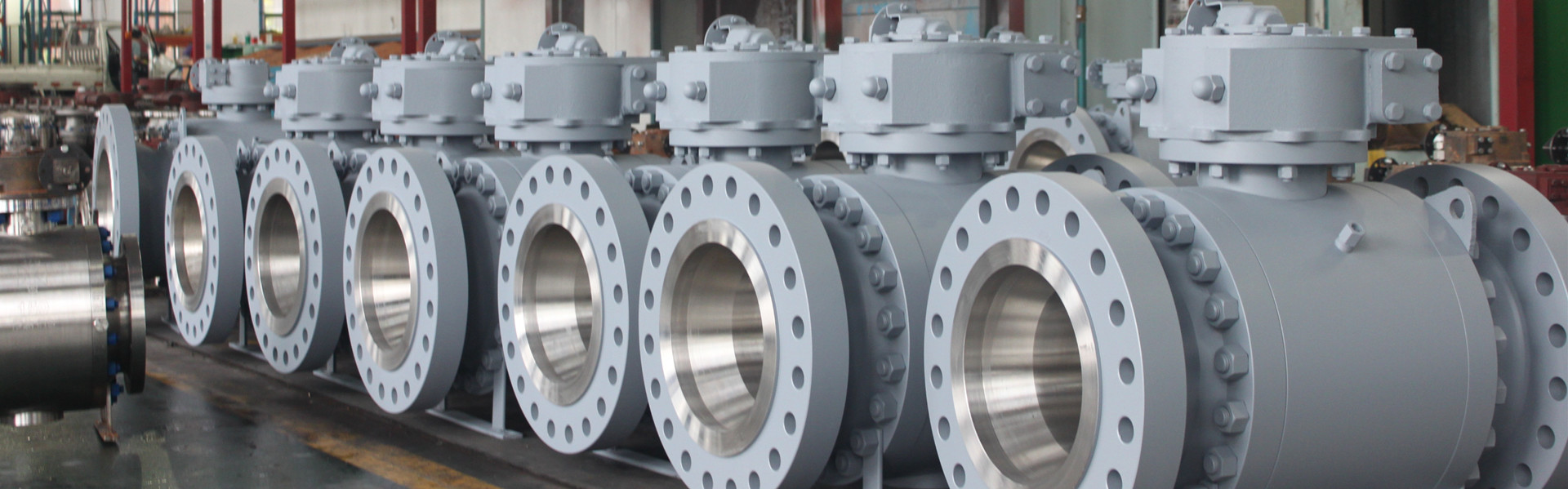

SIZE RANGE AND PRESSURE CLASS

Size from 2” to 40” (DN50-DN1000)

Pressure from 150LBS to 1500LBS (PN16-PN240)

DESIGN STANDARDS

Design / Manufacture as per the standards

API 6D; ASME B16.34; DIN 3357; EN 13709; GB/T12237; BS5351

Face to Face Length (Dimension) as per the standards

ASME B16.10; EN 558-1 Gr. 14 (DIN 3202-F4); DIN 3202-F5; DIN 3202-F7; BS5163

Flanged Dimension according to the standards

ASME B16.5; EN 1092-1; BS4504; DIN2501;

Flanged to ASME B16.5 (2” ~ 24”) and ASME B16.47 Series A / B (26” and above) Clamp / Hub ends on request.

Testing according to the standards

API 598; API 6D; EN 12266-1; EN 1074-1; ISO5208

TECHNICAL FEATURES

Two sealing surfaces.

Alloy steel or hard alloy sealing surface good wear resistance and scratch resistance.

Single gate or double gate upon request.

Cast or forged body

Bolted bonnet, pressure seal bonnet

Flow resistance is small

Easy to operate.

Solid Wedge, OS&Y design

Bi-directional contraction

CONSTRUCTION MATERIALS

General Cast Carbon Steel

A216 WCB (WCC, WCA), GP240GH (1.0619/GS-C25)

Low Temperature Carbon Steel (LTCS), LCB (LCC, LCA), GS-CK25

Alloy Steel:

A352 LC1/LC2/LC2-1/LC3/LC4/LC9/, A743 CA6NM

GS-CK16 GS-CK24 GS-10Ni6 GS-10ni14

High Temperature Steel (Chrome Moly)/Alloy Steel:

A217 WC1/ WC6/ WC9/C5/C12/C12A

GS-22Mo4/ G20Mo5 (1.5419); GS-17CrMo55/ G17CrMo5-5 (1.7357)

Austenitic Stainless Steel/Alloy Steel:

UNS S30400 (S30403) (S30409), A351 CF8/CF3/CF10

G-X6CrNi189/ GX5CrNi19-10(1.4308)

UNS S31600 (S31603) (S31609), A351 CF8M/CF3M/CF10M

GX5CrNiMo19-11-2/G-X6CrNiMo18.10 (1.4408)

UNS S34700 (S34709), A351 CF8C

G-X5CrNiNb189/GX5CrNiNb19-11(1.4552)

AISI316Ti; X6CrNiNo17122/ X6CrNiMoTi17-12-2(1.4571)

ALLOY 20# / UNS N08020, A351 CN7M

Ferritic-Austenitic / Duplex / Super Duplex Stainless Steel:

UNS S31803 /S32205 (Duplex2205), A890/A995 GR.4A (J92205) /A351 CD3MN

UNS S32750 (Super Duplex2507), A890/A995 GR.5A / A351 CE8MN (CD4MCu)

UNS S32760, A890/A995 GR.6A (CD3MWCuN)

Other materials

Alloy 20 ASTM B462 / UNS N08020

Monel 400 / UNS N04400 ASTM B564-N04400 / A494 M35-1 NiCu30Fe (2.4360)

Nickel Alloy 904L / UNS N08904 X1NiCrMoCu25.20.5 (1.4539)

Inconel 625 /UNS N06625 /ASTM B564-N06625 /ASTM A494-CW6MC

NiCr22Mo9Nb (2.4856)

Inconel 825 /UNS N08825 /ASTM B564-N08825 /A494 CU5MCuC (2.4858)

NiCr21Mo (2.4858)